One Article to Master Laser Doppler Vibrometer: Everything You Need to Know

The Discovery of the Doppler Effect

The Doppler Effect was first discovered in 1842 by Austrian physicist Christian Doppler, who observed changes in the pitch of a train whistle as it approached or receded. With the advancement of physics, it became clear that the Doppler Effect is a universal phenomenon present in all wave phenomena, such as sound waves and light waves.

However, the Doppler Effect for light waves, also known as the Doppler-Fizeau Effect, was utilized in 1848 by French physicist Armand Fizeau to measure the relative velocity of stars. This phenomenon manifests as a change in the color of light (corresponding to a frequency shift) within the visible spectrum: motion towards the observer appears as a blue shift, while motion away appears as a red shift.

Laser Doppler Vibrometer Principle

Leveraging the frequency shift and phase shift characteristics of the Doppler Effect, when coherent laser light is used to measure a vibrating object, the frequency or phase of the laser light becomes modulated, resulting in a Laser Doppler Effect. This manifests as a Doppler frequency shift (fd) and a phase shift (pd). Using laser interferometry, the laser beam reflected from the target object is interfered with a reference laser beam. The resulting interference pattern is detected by a photodetector, yielding Doppler frequency shift (fd) and phase shift (pd) signals. These signals are then demodulated to obtain the physical parameters (displacement, velocity) of the vibrating object. The demodulation methods are based on the following Doppler formulas:

- Doppler Frequency Shift Formula: fd = (2v * cosθ) / λ

Where fd is the Doppler frequency shift, v is the vibration velocity of the measured object, λ is the laser wavelength, and θ is the angle between the laser beam and the object's vibration direction.

- Doppler Phase Shift Formula: Δφ = (4π Δl cosθ) / λ

Where Δφ is the Doppler phase shift, Δl is the vibration displacement of the measured object, λ is the laser wavelength, and θ is the angle between the laser beam and the object's vibration direction.

hese formulas reveal a correlation between Doppler frequency shift and phase shift. Consequently, Laser Doppler Vibrometers (LDVs) utilize two distinct demodulation approaches based on these characteristics: Frequency Discrimination (FM) and Phase Discrimination (PM), to extract vibration velocity and displacement.

Classification of Laser Doppler Vibrometers

Now that we understand the Doppler Effect, how many technical approaches exist for designing a Laser Doppler Vibrometer, and how are current market LDVs classified?

1. Classification by Demodulation Method of Coherent Signal

- Frequency Discrimination (FM) Principle: Employs Phase-Locked Loop (PLL) technology to extract the Doppler frequency shift (fd), directly obtaining the object's vibration velocity (v).

- Phase Discrimination (PM) Principle: Utilizes the In-phase (I) and Quadrature (Q) signals generated after quadrature mixing. The phase difference between the reference and measurement beams, corresponding to the object's vibration displacement (Δl), is obtained using the arctangent formula.

2. Classification by Coherent Light Interference Principle

- Heterodyne Interference: A fixed frequency shift (typically applied using an Acousto-Optic Frequency Shifter - AOFS) is introduced to either the object beam or the reference beam. Interference then produces a frequency-modulated (FM) signal containing a carrier wave, which is subsequently processed.

- Homodyne Interference: The object beam and reference beam interfere directly without frequency shifting, producing a Doppler frequency-modulated signal near baseband (zero frequency, carrierless). Optical methods generate the simultaneous I and Q signals required for phase discrimination demodulation, yielding phase (Δφ) directly proportional to the object's relative vibration displacement (Δl).

Homodyne vs. Heterodyne: Performance Comparison

Traditionally, homodyne systems were considered more susceptible to low-frequency noise due to the baseband signal. Heterodyne systems, operating with a higher carrier frequency (typically tens of MHz), were seen as more immune to environmental noise, potentially offering higher precision. However, breakthroughs in noise reduction technologies now enable homodyne systems to match heterodyne performance while retaining inherent advantages: lower cost, reduced heat generation, and greater suitability for miniaturization and integration.

Heterodyne systems face disadvantages: they significantly increase system cost. High-performance AOFS units are expensive. The high carrier frequency demands higher-speed Analog-to-Digital (AD) converters and more powerful FPGA processors for digital signal processing. Increased component specifications also lead to higher power consumption and heat dissipation. Consequently, heterodyne laser interferometers are typically bulky, requiring separate measurement heads and demodulation units. While integrated systems exist, they generally offer lower performance specifications.

3. Classification by Chip Design Type

- Electronic Integrated Circuit (EIC): Traditional LDVs are based on EIC design, integrating components onto large circuit boards. Drawbacks include large size, limited performance, and high cost.

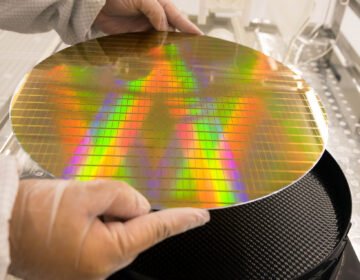

- Integrated Photonic Circuit (OIC - Optoelectronic Integrated Circuit): Just as electronic circuits evolved into integrated circuits (ICs), optical circuits are advancing towards Integrated Photonic Chips (OICs). Optical waveguide technology forms the foundation of integrated optics. OIC technology represents an industrial upgrade for photoelectric sensors. Characterized by compact size, high performance, low power consumption, and lower cost, OICs are poised to progressively replace traditional EIC-based designs, offering innovative solutions for the global precision instrumentation industry.

Introducing the Compact Laser Doppler Vibrometer

The Compact Laser Doppler Vibrometer features miniaturization, high integration, cost-effectiveness, and high precision. Core technologies include the application of Integrated Photonic Chips (OIC), advanced module packaging, and sophisticated modulation/demodulation algorithms.

Take OmniSensing micro Laser Doppler Vibrometer as an example. Its design is based on the homodyne phase discrimination principle and utilizes a proprietary Integrated Photonic Chip (patent-protected). This chip simultaneously outputs up to 8 optical signals: 4 measurement signals and 4 reference signals used for subsequent algorithmic noise reduction. Real-time noise reduction and signal demodulation are performed by an FPGA. This approach represents the cutting edge of industry development, foreshadowing its adoption in an increasing number of advanced industrial measurement products. #LaserVibrometer #LaserDopplerVibrometer