Aerospace

Captures nonlinear vibration params of complex parts (thin walls, fan blades), performs ODS/modal analysis via multi-channel sync in high-temp environments.

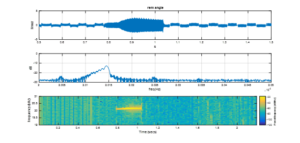

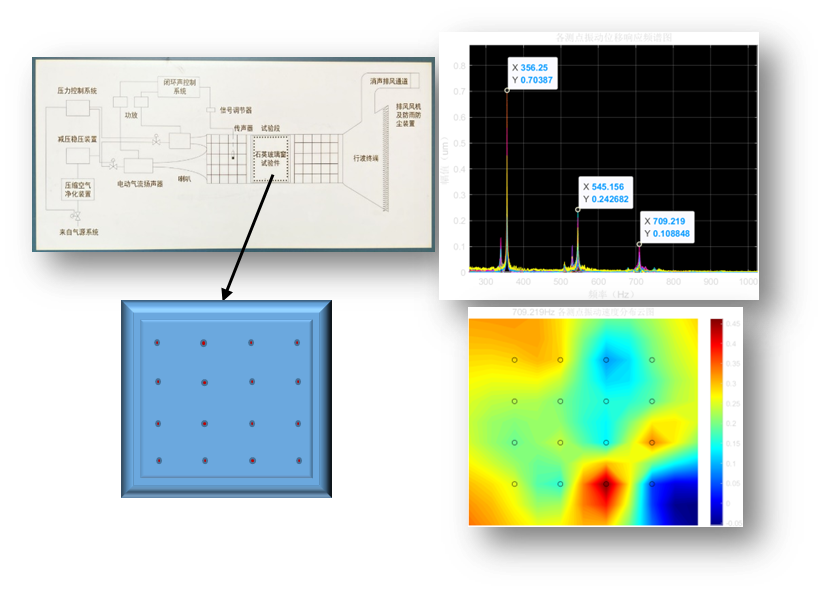

ODS Analysis of Aviation Thin-Walled Panels under High-Temperature

Experimental Setup:

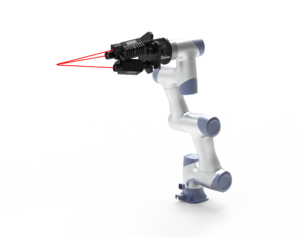

- Two micro laser Doppler vibrometers

- XY mobile platform device

- High-temperature thin-walled panel acoustic fatigue test bench

- Online signal monitoring and analysis software

Results Analysis:

- Through spectral analysis, the structural vibration peak frequencies of the thin-walled panel below 1000 Hz are obtained as 356.25 Hz, 545.16 Hz, and 709.22 Hz, respectively.

- Through ODS analysis, operational deflection shape contour plots of the thin-walled panel under acoustic excitation at these three frequencies are obtained.

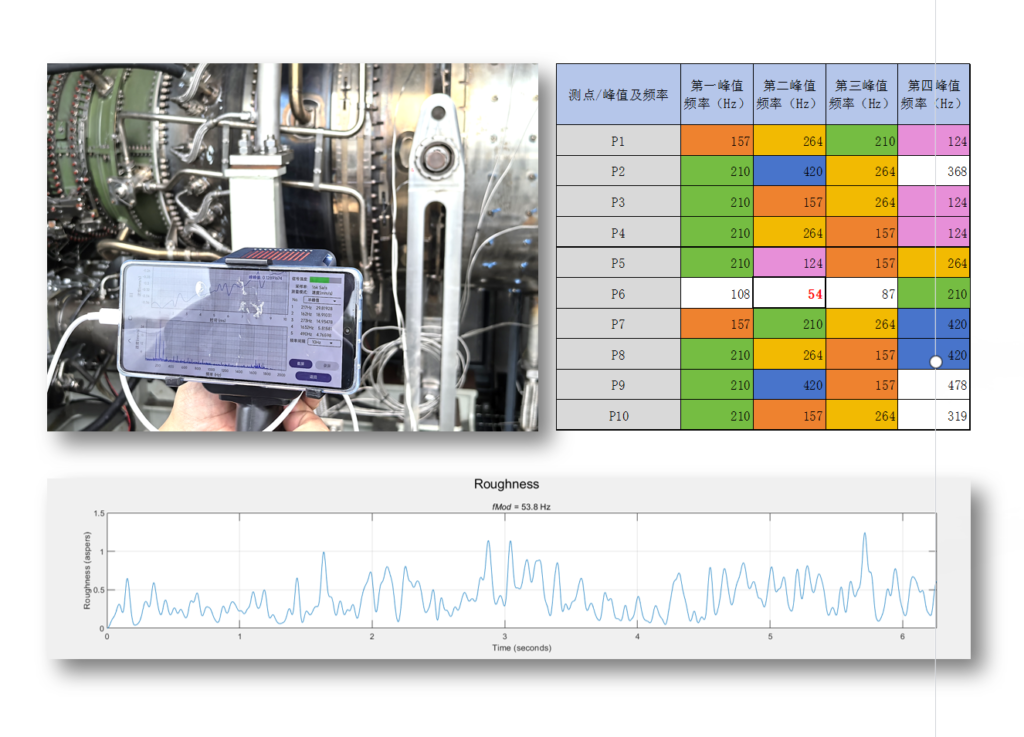

Vibration and Abnormal Noise Fault Diagnosis of Gas Turbine

The right figure summarizes the analysis results of 10 different vibration measurement points on an aero-engine gas turbine. The 124Hz frequency corresponding to the low-pressure rotor is found at points 1, 3, 4, and 5, but it is not a main contributor to the amplitude. The 210Hz frequency corresponding to the high-pressure rotor is detected at all 10 measurement points, and it is a main amplitude contributor for most of them.

Additionally, the sidebands of 210Hz—157Hz and 264Hz—are found at points 1, 3, 4, 5, 7, 8, and 10. The modulation frequency of 54Hz and its second harmonic are detected at point 6. Therefore, it is suspected that the cause of the sidebands in the high-pressure rotor may be related to an abnormal structure near point 6.

Finally, the second harmonic of the high-pressure rotor frequency (210Hz) is simultaneously observed at points 2, 7, 8, and 9, though their amplitude contributions are minor.

For more case inquiries, please contact OmniSesning

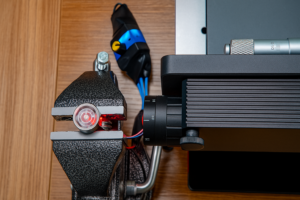

Application of Compact Laser Vibrometer in UAV Motor Shaft Runout Testing

Non-Contact Modal Measurement System

Revolutionary Vibration Monitoring for Next-Gen Range-Extender Engines: The OmniSensing MotionGo Laser Doppler Vibrometer Solution

Motor Shaft Runout and Yaw: Causes, Impacts, and Non-Contact Detection Solutions