Motor Shaft Runout and Yaw: Causes, Impacts, and Non-Contact Detection Solutions

OmniSensing – Precision motor performance is critical for industrial efficiency. Shaft runout and yaw remain persistent challenges, leading to downtime and costly repairs. This analysis explores root causes, impacts, and compares three advanced non-contact laser vibrometer solutions – highlighting the superior capabilities of laser Doppler vibrometry for dynamic fault diagnosis.

I. Causes of Motor Shaft Runout/Yaw

- Manufacturing Defects: Bent/twisted shafts from machining or heat treatment errors.

- Installation Errors: Incorrect bearing fits, loose foundations, or unstable bases.

- Operational Stress: Torque fluctuations or external load variations.

- Maintenance Gaps: Poor lubrication practices accelerating wear.

II. Critical Impacts on Operations

- Reduced efficiency + increased noise/vibration

- Accelerated bearing wear & premature failure

- Unplanned downtime and production losses

III. Solution 1: Laser Doppler Vibrometer Technology

Overview

Laser Doppler vibrometers (LDVs) enable non-contact, high-precision measurement of shaft dynamics without disrupting operations – ideal for real-time industrial monitoring.

Detection Principle

LDVs utilize the Doppler effect: A laser beam reflects off vibrating surfaces, inducing frequency/phase shifts. These shifts are decoded into nanometer-level displacement data, precisely quantifying runout/yaw.

Key Advantages

- ✅ Non-contact: Zero mechanical interference

- ✅ Nanometer precision: Superior accuracy

- ✅ Real-time bandwidth: Up to MHz sampling

IV. Non-Contact Solution Comparison

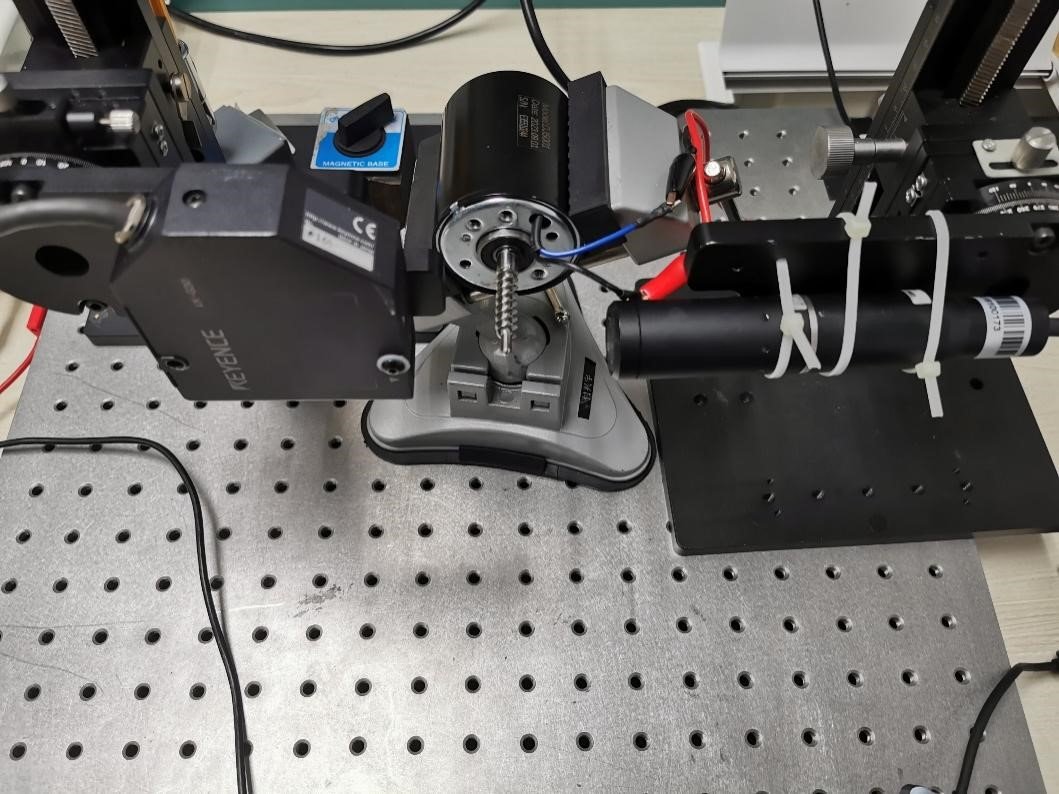

Test setup: 12V motor @ 1,800 RPM, 3.92mm shaft diameter

Figure 1:White-Light Confocal &Triangulation Laser

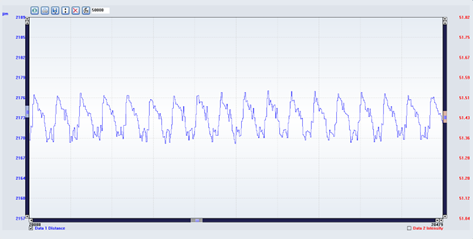

1. STIL White-Light Confocal

- Limited high-frequency response (~9μm runout)

- Low resolution: Misses harmonic details

- Short working distance: Restricted applicability

Figure 2:STIL White-Light Confocal test result

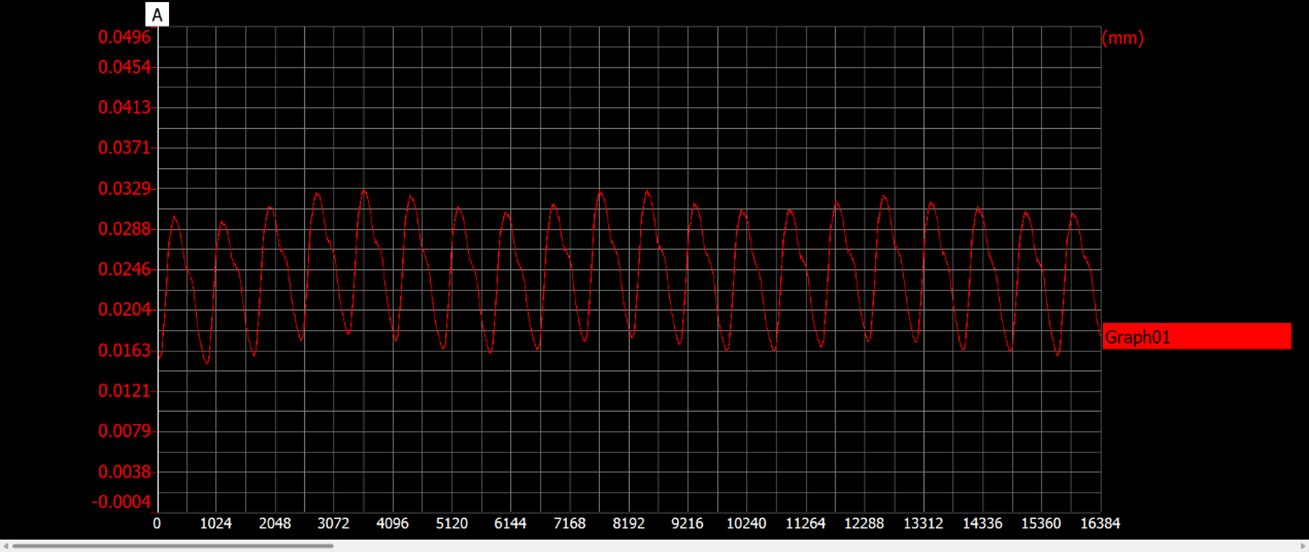

2. Keyence Triangulation Laser

- Data averaging masks true peaks (~14μm runout)

- CCD resolution limits: Fails to capture vibration harmonics

- Unsuitable for advanced vibration analysis

Figure 3:Keyence Triangulation Laser test result

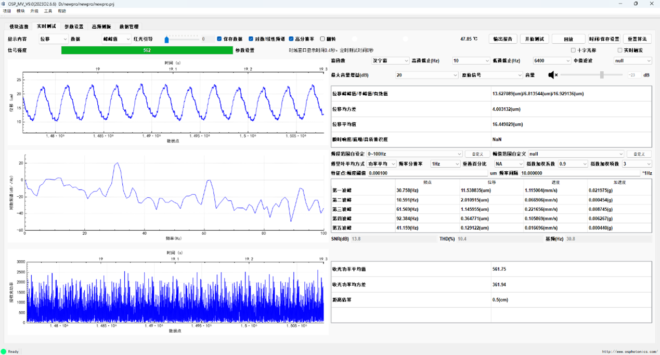

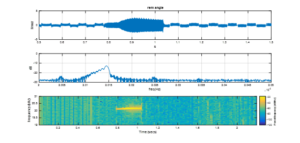

3. OmniSensing Laser Doppler Vibrometer

- Precision: 13.6μm runout @ 0.001nm resolution

- Bandwidth: 5MHz sampling captures full vibration spectrum

- Diagnostic Power: Identifies harmonics (e.g., 61.569Hz @ 1.146μm)

- AI-Ready: Time-frequency analysis enables predictive maintenance

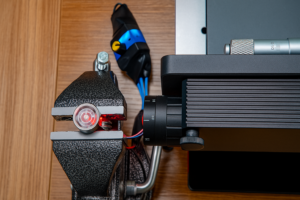

Figure 4:OmniSensing Laser Doppler Vibrometer setup

Figure 5:OmniSensing Laser Doppler Vibrometer test result

| Technology | Runout | Resolution | Harmonic Analysis | AI Diagnostic Support |

|---|---|---|---|---|

| STIL Confocal | ~9μm | Low | ❌ | ❌ |

| Keyence Triangulation | ~14μm | Medium | ❌ | ❌ |

| OmniSensing LDV | 13.6μm | 0.001nm | ✅ | ✅ |

V. Conclusion: Why Laser Doppler Vibrometry Prevails

OmniSensing’s laser Doppler vibrometer outperforms triangulation and confocal solutions with:

- Nanometer-level resolution for micro-vibration detection

- Ultra-wide bandwidth capturing critical harmonics

- Non-contact precision suitable for automated industrial systems

- Structured data outputs for AI-driven fault diagnosis

This makes LDV technology indispensable for next-gen predictive maintenance and Industry 4.0 automation.

About OmniSensing

OmniSensing pioneers advanced photonics solutions, specializing in high-precision laser Doppler vibrometers for industrial diagnostics. Our sensors enable AI-ready vibration analysis, reducing downtime and optimizing operational efficiency. Explore our LDV solutions →

Application of Compact Laser Vibrometer in UAV Motor Shaft Runout Testing

Revolutionary Vibration Monitoring for Next-Gen Range-Extender Engines: The OmniSensing MotionGo Laser Doppler Vibrometer Solution

Motor Shaft Runout and Yaw: Causes, Impacts, and Non-Contact Detection Solutions

Omnisensing Photonics’ Non-Invasive and Online Monitoring Solution for Industrial Ultrasonic Welding