MotionGo 3D Laser Doppler Vibrometers

Three-dimensional laser Doppler vibrometer

Product description:

The MotionGo 3D (Micro 3D Laser Doppler Vibrometer) from OmniSensing is a high-end vibration measurement instrument centered on an integrated optical chip. It combines a compact design with precise homodyne interference and phase detection demodulation algorithms, designed to provide high-precision, non-contact 3D vibration measurement solutions for diverse fields such as NVH (Noise, Vibration, and Harshness), university research, industrial manufacturing, and material science.

Compared with traditional single-point laser Doppler vibrometers, MotionGo 3D utilizes professional 3D coordinate calibration and transformation algorithms to accurately acquire vibration displacement, velocity, and acceleration data of target objects in the X, Y, and Z directions. This capability fully presents the true vibration state of objects in spatial dimensions, offering comprehensive data support for complex structural dynamics analysis, multi-degree-of-freedom system modal analysis, and other applications.

MotionGo 3D stands out from similar products with its distinct advantages: small size, lightweight, and low power consumption, with a total weight just a few tenths of that of conventional counterparts. Such a super-compact form factor makes it highly adaptable for integration into automation equipment like robotic arms and pan-tilt systems. The device features high adaptability and expandability, providing both digital and analog signal output options to facilitate integration with domestic and international data acquisition devices for 3D vibration and modal measurements. Additionally, to meet customers’ personalized needs, Sensapex Photonics provides an SDK (Software Development Kit) for secondary software development.

Product Features:

Based on silicon-based optical chips;

Non-contact vibration measurement;

3D spatial measurement capability;

Compact size, lightweight, and easy integration;

Precise angle calibration and transformation methods;

High adaptability and scalability, supporting co-debugging with domestic and international data acquisition devices;

User-friendly operation and data output in multiple formats.

MotionGo 3D Specifications:

Working Parameters:

Working Distance: 40 cm (default, customizable).

Depth of Field: ±0.5 cm (at 40 cm working distance).

Sampling Rate: 5 million samples per second (5 Msps).

Frequency Range: DC to 500kHz (covers static to ultra-high-frequency vibrations).

Precision:

Displacement Resolution:

In-Plane (X/Y): 10 nm.

Out-of-Plane (Z): 100 nm.

Velocity Resolution: 0.1 mm/s.

Accuracy: <5% of full scale (FS) for X/Y/Z displacements.

Velocity Ranges:

In-Plane (X/Y): Up to 12 m/s.

Out-of-Plane (Z): Up to 1.5 m/s.

Optical System:

Measurement Laser: 1310 nm (infrared, non-visible).

Alignment Laser: 655 nm (visible red).

Lens: Fixed focus.

Design and Connectivity:

Channels: 3 (X, Y, Z axes).

Communication: Ethernet (high-speed data transfer).

Power Supply: DC 5–20V (flexible for industrial use).

Weight: <900 g (portable).

Durability: IP63 rating (dust-resistant and water-resistant).

Calibration: Factory-calibrated (no user recalibration required).

*Regarding the specifications of MotionGo 3D Pro, please download the PDF technical document for reference.

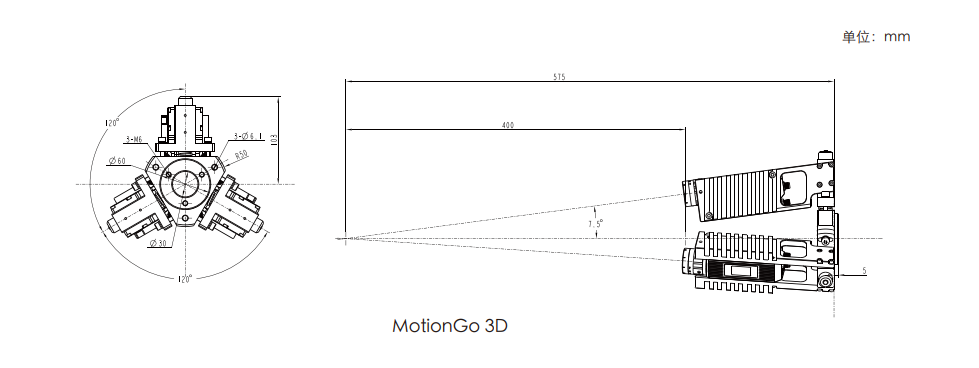

Outline and dimensions: