MSV-660 Automatic Non-Contact Modal Measurement System

Product description:

OmniSensing scanning non-contact modal measurement system is an integrated solution integrating high-precision laser measurement, flexible mechanical scanning, and professional modal analysis. It consists of three core parts:

Laser sensor: Osphotonics MotionGo MVS miniature full-function auto-focus laser Doppler vibrometer, which realizes non-contact high-precision vibration signal acquisition;

Scanning device: CRA series collaborative robot, providing global spatial scanning movement capability and accurately positioning measurement points;

Modal analysis software: N-Modal V6.0 modal analysis software, which completes data processing, modal parameter identification, and visual display.

Through the collaboration of the three, the system can efficiently obtain dynamic characteristic parameters such as natural frequency, damping ratio, and mode shape of structures. It is widely applicable to modal tests and analyses in fields such as industrial manufacturing, aerospace, and construction engineering, providing a scientific basis for structural optimization, fault diagnosis, and health monitoring.

Product Features:

The laser vibrometer features a miniaturized and integrated design, weighing only 500g.

0.3-4m auto-focus ensures good return light intensity.

No need to spray or paste reflective materials on the measurement surface.

Dual digital and analog output, supporting secondary development.

With a movement accuracy of 20 microns and 360-degree spatial rotation, the laser vibrometer can always maintain vertical measurement, reducing angle measurement errors.

A maximum scanning radius of 1700mm, adapting to larger measured objects.

The modal analysis software has ODS, EMA, and OMA analysis functions, and various mainstream modal parameter identification methods.

Supports Chinese and English bilingual interface parameter items.

Hardware Part:

MVS Miniature Full-Function Auto-Focus Laser Doppler Vibrometer

MotionGo MVS is a miniature laser vibrometer customized for medium and long-distance harsh environments. Based on a highly integrated silicon optical chip, it integrates optical coherent optical paths and modulation optical paths into a single chip. It is only palm-sized (120×50×60mm) and can be flexibly integrated into robots, drones, and other platforms. Equipped with an auto-focus lens and built-in data processing and units, it supports a 5M sps sampling rate, can accurately measure vibration signals from DC to 2.5MHz, and output both digital and analog results, adapting to traditional measurement systems and large-scale networked synchronous measurement needs.

Product Features:

Miniaturized design: Weighing only 570g, it is small in size and easy to integrate at the end of the mechanical arm without affecting the movement performance of the scanning device;

Synchronous expansion: Supports multi-channel synchronous measurement (synchronization accuracy 0.2μs), with trigger/synchronization input and output interfaces, and can work with external sensors to adapt to synchronous analysis of multiple measurement points of complex structures;

High-precision measurement: Displacement resolution is 0.01nm, noise density is as low as 0.1pm/√Hz, and displacement repeatability (>1kHz) reaches 0.01nm, taking into account both static displacement and high-frequency vibration (such as ultrasonic materials) measurement;

Intelligent adaptation: 0.2-4m measurement distance, no need to replace the auto-focus lens, 655nm red light indication for auxiliary positioning, supporting 24-level analog output sensitivity automatic adjustment;

Strong environmental adaptability: IP64 protection level, anti-glare interference capability >60000Lux, operating temperature 0~50℃, suitable for industrial sites, high/low temperature and other harsh environments.

Performance Parameters:

| Parameters (Unit) | Values | Parameters (Unit) | Values |

|---|---|---|---|

| Measurement distance (m) | 0.3~4 | Data output rate (sps) | 5M |

| Measurement displacement accuracy (nm) | 0.1 | Maximum measurement speed (m/s) | 20 |

| Measurement displacement resolution (pm) | 1 | Measurement depth of field (relative to focus distance) | 10% of the test distance |

| Laser (nm) | 1310 (measurement light) | Measuring laser output power (mW) | <5 |

| Measuring laser safety class | CLASS I | Stray light interference (lux) | >60000 |

| Digital output signal interface | Ethernet 100BaseT | Protection class | IP63 |

| Operating temperature range (℃) | 0~50 | Housing material | Aluminum alloy |

| Supply voltage (V) | DC12 | Power consumption (W) | <3 |

| Dimensions (mm) (Length * Width * Height) | 120*50*60 | Weight (g) | 570 |

2.Scanning Device: CRA Series Collaborative Robot

Product Introduction:

The CRA series collaborative robots are the core scanning execution units of the system, covering seven models from CR3A to CR20A, with a load range of 3~20kg and a working radius of 620~1700mm, which can meet the global scanning needs from small components to large structures. It adopts a lightweight design, supports any installation method such as forward and reverse installation, and is equipped with high-precision motion control and multiple safety protections to provide stable and accurate spatial positioning support for the laser sensor.

Product Features:

Flexible deployment: The body weight is 16.5~70kg, and the volume is compact;

High-precision movement: Repeat positioning accuracy is ±0.02~±0.1mm, equipped with micron-level anti-shake technology;

Efficient response: The maximum joint speed reaches 223°/s, and the maximum linear speed is 2m/s;

Safe collaboration: It has 20 safety functions such as collision detection, safety skin, and virtual wall, passed ISO13849 and TS15066 certifications, and can realize human-machine collaboration without guardrails;

Expansion and compatibility: Supports EtherCAT, Modbus and other industrial communication protocols, can be directly connected to industrial PC, PLC and other systems, and is compatible with more than 100 end ecological accessories.

Performance Parameters:

| Parameters (Unit) | Values | Parameters (Unit) | Values |

|---|---|---|---|

| Body weight (kg) | 16.5-70 | Rated load (kg) | 3-20 |

| Working radius (mm) | 620-1700 | Maximum linear speed (m/s) | 2 |

| Joint movement range | J1/J2/J4/J5/J6: ±360°; J3: ±155°~±165° | ||

| Maximum joint speed | J1/J2: 180°/s; J3/J4/J5/J6: 223°/s | ||

| Repeat positioning accuracy (mm) | 0.02-0.1 | Stray light interference (lux) | >60000 |

| Operating temperature range (℃) | 0~50 |

Software Part:

1.N-Modal Modal Analysis Software V6.0

Product Introduction:

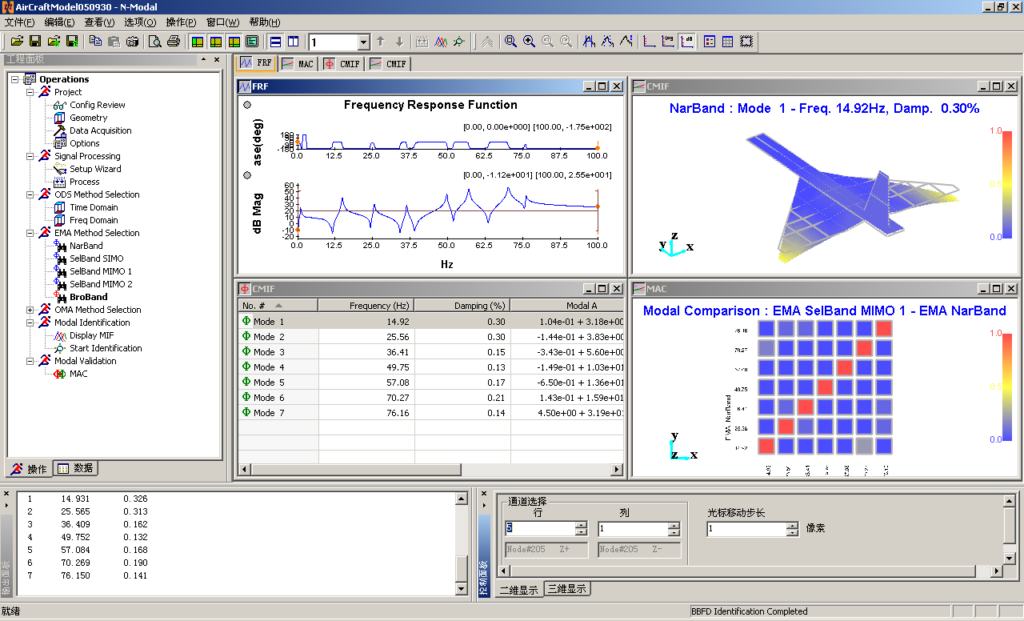

N-Modal V6.0 is a professional modal analysis software jointly developed by OmniSensing and Nanjing University of Aeronautics and Astronautics. It supports three core functions: Operational Deflection Shape (ODS) analysis, Experimental Modal Analysis (EMA), and Operational Modal Analysis (OMA). It can process full-scene modal test data from artificial excitation to environmental excitation, and realize accurate identification and visual display of parameters such as natural frequency, damping ratio, and mode shape of structures.

Product Features:

Full-scene analysis: Supports time-domain/frequency-domain ODS (response mode), multi-input multi-output (MIMO) EMA (experimental mode), and environmental excitation OMA (operational mode), covering full-scene tests from laboratory to on-site;

Efficient identification algorithms: Integrates three types of algorithms: narrowband (NarBand), selected band (SelBand), and broadband (p-LSCF), which can identify dense modes and repeated frequency modes, and obtain full-frequency band modal parameters in one analysis;

Powerful signal processing: Supports FFT transformation, multiple window functions (Hanning window, flat-top window, etc.), power spectrum/frequency response function estimation, adapting to preprocessing needs of different signal characteristics;

Visual interaction: Provides 2D curves (frequency response function, phase diagram), 3D mode shape animation, MAC matrix (mode shape accuracy inspection) and other visualization functions, supporting animation export to MP4/GIF format;

Flexible compatibility: Supports UFF universal format data import/export, can connect mainstream data acquisition equipment at home and abroad, adapts to Windows 7/10/11 systems, and provides Chinese and English bilingual interfaces.

Performance Parameters:

| Supported analysis types | ODS (time domain/frequency domain), EMA, OMA |

|---|---|

| Modal identification algorithms | Narrowband (NarBand), selected band (SelBand), broadband (p-LSCF) |

| Signal processing capability | FFT length (base 2 integer), overlap rate 0%~83%, multiple window functions |

| Data interface | Supports UFF 58/58b, ASCII format import/export |

| Visual output | 2D curves, 3D mode shape animations (supporting MP4/GIF export), MAC matrix |

| Operating system compatibility | Windows 7/10/11 (64-bit) |

| Language support | Chinese and English bilingual (other languages can be customized) |

Function Module Selection Table:

| Model | Function Description |

|---|---|

| NMOD 300 | Operational Deflection Shape (ODS) analysis, including time-domain/frequency-domain ODS and modal quick view functions |

| NMOD 350D | SIMO/MIMO Experimental Modal Analysis (EMA), including narrowband, selected band, and broadband identification algorithms |

| NMOD 370D | Operational Modal Analysis (OMA), including broadband identification algorithms |

| NMOD 380 | Full-function module, including ODS, EMA, and OMA functions |

If you have any questions, please call us or send an email to globalsales@osphotonics.com.

Headquarters: OmniSensing (Suzhou) Photonics Technology Co., Ltd.

Address: 7th Floor, Building 1, Wujiang Technology Entrepreneurship Park, No. 2358 Chang’an Road, Wujiang District, Suzhou

Official website: www.ospmotiongo.com

Contact number:

Consultation hotline: 4006-899-870