Household Devices

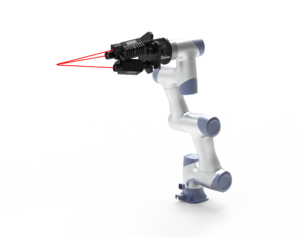

OmniSensing MLDVs offer non-contact, high-precision vibration analysis for home appliances, ensuring motor reliability, noise reduction, and quality optimization in manufacturing.

Compressor pipeline vibration analysis

Leading manufacturers leverage LDVs to comply with stringent noise regulations (e.g., ISO 3745 for sound power measurement) and enhance product durability. For example, in dishwasher production, LDV-based quality control reduces warranty claims related to tub fatigue by 15% . Additionally, LDVs enable the development of quieter, more energy-efficient appliances, aligning with consumer demands for sustainable home technology.

Laser Doppler Vibrometers are pivotal in advancing the performance and reliability of white goods, offering a blend of precision measurement, non-intrusive testing, and actionable insights for engineering innovation.

Leading manufacturers leverage LDVs to comply with stringent noise regulations (e.g., ISO 3745 for sound power measurement) and enhance product durability. For example, in dishwasher production, LDV-based quality control reduces warranty claims related to tub fatigue by 15% . Additionally, LDVs enable the development of quieter, more energy-efficient appliances, aligning with consumer demands for sustainable home technology.

In summary, Laser Doppler Vibrometers are pivotal in advancing the performance and reliability of white goods, offering a blend of precision measurement, non-intrusive testing, and actionable insights for engineering innovation.

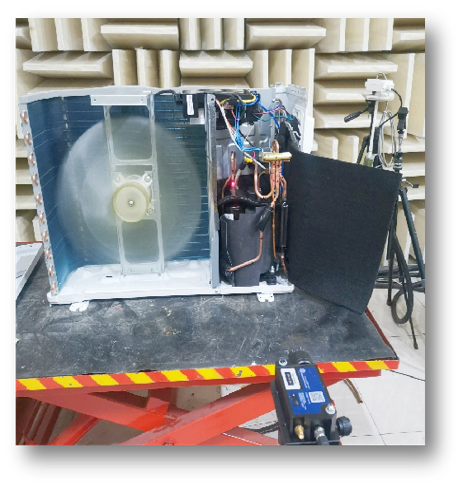

Experimental Setup:

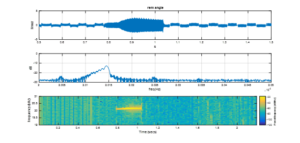

- Test Objective: Non-contact vibration measurement of compressor pipelines

- Test Equipment: Micro laser Doppler vibrometer

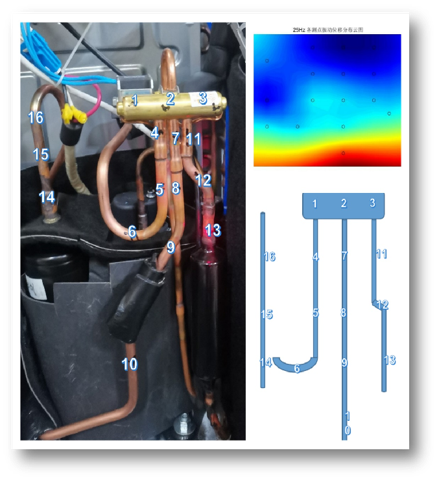

- Measurement Locations: 16 measurement points distributed across 4 pipelines

- Analysis Methods: Frequency domain analysis and vibration displacement contour plot analysis

Results Analysis:

Through frequency domain and displacement contour plot analysis, the resonance frequencies of the compressor pipelines and the overall vibration amplitude distribution at these frequencies can be quickly obtained, enabling rapid localization of pipeline resonance regions.

More Application Examples in This Field:

Case studies such as dishwasher damping optimization and vibration testing of a brand's electric shaver.

For more case inquiries, please contact OmniSesning

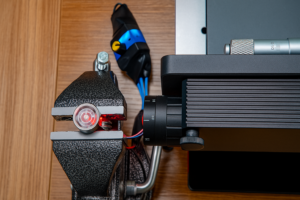

Application of Compact Laser Vibrometer in UAV Motor Shaft Runout Testing

Non-Contact Modal Measurement System

Revolutionary Vibration Monitoring for Next-Gen Range-Extender Engines: The OmniSensing MotionGo Laser Doppler Vibrometer Solution

Motor Shaft Runout and Yaw: Causes, Impacts, and Non-Contact Detection Solutions