OmniSensing Laser Doppler Vibrometer: Compact Design, High Performance & Low Price

Introduction

In precision vibration analysis, engineers and researchers demand high performance, small form factors, and cost-effectiveness. OmniSensing has redefined the market with its compact laser Doppler vibrometer, offering a laser vibrometer price that opens advanced non-contact vibration measurement to a broader audience. Designed for seamless integration and future-ready data workflows, OmniSensing excels both in the lab and on the production line.

1. Best-In-Class Affordability

Competitive Laser Vibrometer Price

Traditional LDVs often exceed $20,000-70,000; OmniSensing delivers comparable sensitivity and dynamic range at up to 50% lower cost or more.Reduced Operating Costs

- Solid-state photon-chip components minimize drift and maintenance.

Low power draw keeps energy bills down.

Minimal recalibration required, saving time and service fees.

2. Ultra-Compact, Plug-and-Play Integration

Palm-Sized Footprint

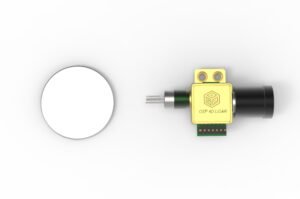

Weighing under 86 g and measuring just 58 × 34 × 22 mm, OmniSensing fits on optical tables, robotic arms, or even UAVs.Standardized Connectivity

USB-C, Ethernet, and a RESTful API enable plug-and-play setup—ideal for automated quality-control and Industry 4.0 systems.Portable & Robust

IP64-rated enclosure withstands harsh environments, making field deployment and mobile diagnostics effortless.

3. Photon-Chip Technology: Small Device, Big Impact

At the heart of every OmniSensing LDV lies an integrated photon chip, which:

Boosts Signal-to-Noise Ratio (SNR) for clean data on matte or moving surfaces

Extends Bandwidth up to 5 MHz for high-frequency modal analysis

Eliminates Bulk Optics, reducing size and alignment complexity

Enhances Stability, delivering repeatable results over long test runs

By leveraging wafer-scale photonics, OmniSensing packs the precision of traditional systems into a fraction of the size—and at a fraction of the cost.

4. Online monitoring and secondary development

Machine-Learning-Friendly Formats

Export vibration datasets in CSV, Mat, or Txt—seamlessly integrate with Python, MATLAB, or TensorFlow workflows.Supports real-time online monitoring function, which can display the time-domain charts and linear spectrum diagrams of displacement, velocity and acceleration in real time.

5. Versatile Applications Across Industries

| Industry | Use Case | OmniSensing Advantage |

|---|---|---|

| Aerospace | Modal/Fatigue Testing | High-frequency capture |

| Automotive | NVH (Noise, Vibration, Harshness) | Fast, multi-point deployment |

| MEMS & Semiconductor | Surface-acoustic wave inspection | Sub-micron resolution |

| Structural Health | Bridge & Building Monitoring | Remote, long-term stability |

| Medical Devices | Micro-vibration in Implant Testing | Non-invasive, high-precision

|

Conclusion & Call to Action

OmniSensing’s compact laser Doppler vibrometer brings together low price, high performance, and future-proof connectivity—making it the go-to choice for R&D labs, OEMs, and quality-control engineers.

👉 Learn more or request a quote at ospmotiongo.com