AutoMotive

Supports NVH optimization for vehicles/parts via multi-channel sync measurement and modal analysis, offering efficient data support for automotive R&D and quality control.

Automotive NVH Testing

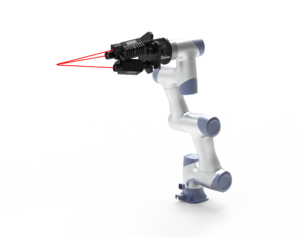

OmniSensing Micro Laser Doppler Vibrometer, due to its advantages such as small size, light weight, and simple operation, is used by vibration and acoustic analysis departments in various industries for rapid vibration detection and fault diagnosis applications.

As shown in the left figure, an automotive brand conducts vibration preliminary tests on positions such as the engine, steering wheel, interior parts, intake and exhaust systems, pipelines, and door panels in a rolling - road laboratory to determine whether they meet the enterprise vibration standard.

More relevant application examples in this field include:

vibration test for automotive body - in - white damping optimization, non - contact modal test for automotive body - in - white, door - closing vibration test, automotive suspension vibration displacement test, tire natural frequency test, and so on.

Automotive Seat Headrest Bracket Vibration Test

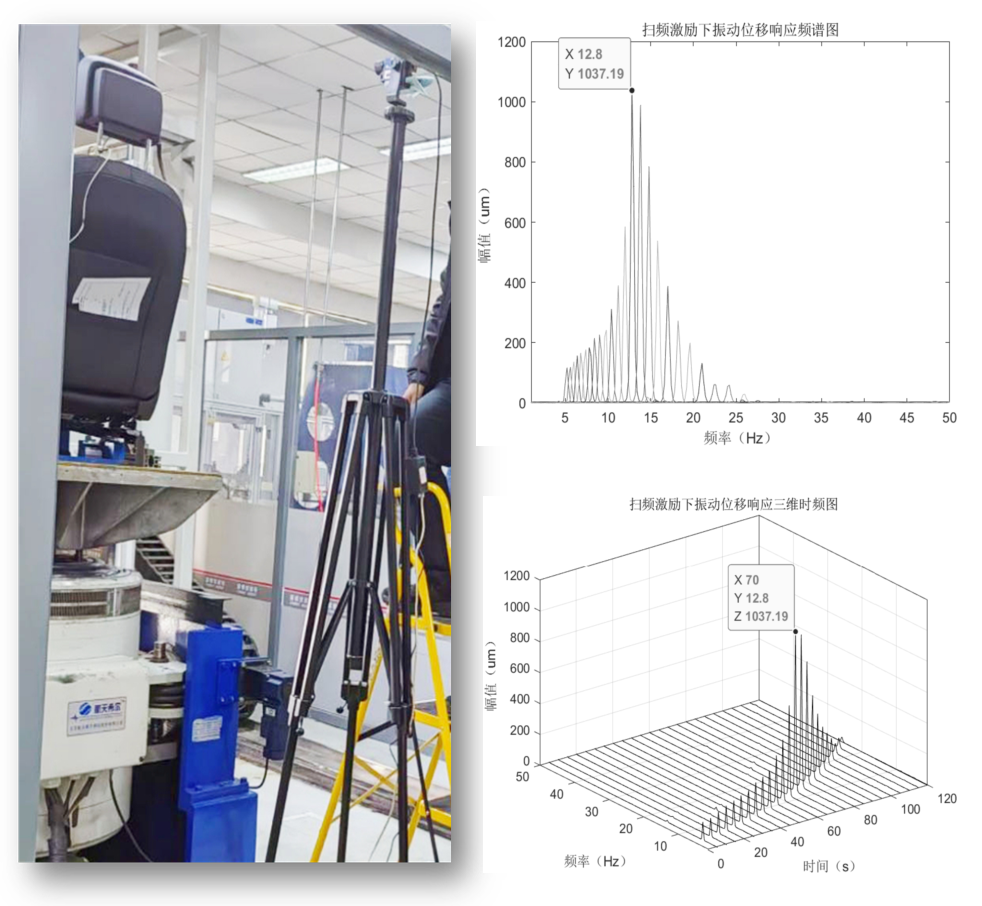

Experimental Setup:

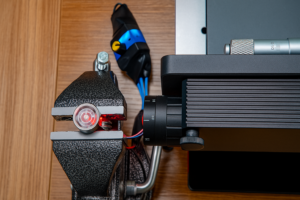

- Micro Laser Doppler Vibrometer

- Vibration Table (swept - frequency excitation)

- Test Point (Seat Headrest Bracket)

- Data Acquisition and Analysis Software

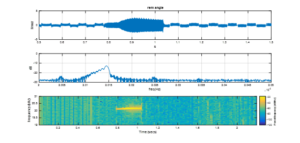

- Matlab Post - processing and Analysis of Data

Result Analysis: After frequency - domain and time - frequency analysis, it can be clearly seen that the natural frequency of the seat bracket is 12.8Hz, and the displacement amplitude is 1.03719mm.

For more case inquiries, please contact OmniSesning

Application of Compact Laser Vibrometer in UAV Motor Shaft Runout Testing

Non-Contact Modal Measurement System

Revolutionary Vibration Monitoring for Next-Gen Range-Extender Engines: The OmniSensing MotionGo Laser Doppler Vibrometer Solution

Motor Shaft Runout and Yaw: Causes, Impacts, and Non-Contact Detection Solutions