LDV Testing Solution for Medical Ultrasonic Scalpels

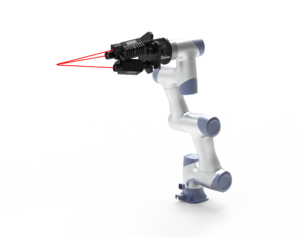

Suitable for vibration precision measurement of ultrasonic equipment such as ultrasonic scalpel, ultrasonic transducer and ultrasonic machine tool.

Ultrasonic surgical scalpels achieve coagulation and hemostasis of incised tissue through heat generated by high-frequency vibrations at the blade tip. The amount of heat produced is related to both the vibration frequency and amplitude. At a given frequency, the amplitude directly impacts cutting performance. Therefore, vibration amplitude is a critical parameter in the research, development, and manufacturing of ultrasonic scalpels.

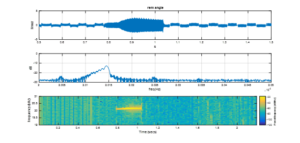

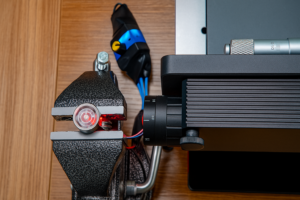

Figure 1 illustrates a vibration testing scenario for an ultrasonic hemostatic scalpel along with a custom-designed fixture. Figure 2 shows the measurement results displayed by the software paired with the laser vibration sensor. These measurements capture key parameters such as the spectral characteristics, peak frequency, and peak amplitude of the device under test. As demonstrated in the video, the custom fixture system and MotionGo sensor enable rapid blade changes and synchronized measurements within seconds, followed by automatic result analysis. This provides an efficient full-inspection solution for ultrasonic scalpel production lines.

The blade tip of the ultrasonic scalpel generates high vibrational energy, with typical frequencies around 55 kHz, vibration amplitudes exceeding 50 microns, and vibration velocities reaching over 20 meters per second. At the same time, the tip is small, curved, and difficult to access, causing significant variation in reflected laser signals. These factors present a major challenge for traditional Doppler vibrometers based on discrete components. MotionGo, with its patented demodulation algorithm, can easily and rapidly complete these measurements, fully demonstrating its superior performance.

For more detailed information on the measurement solution, please download the Omnisensing Photonics white paper.

Application of Compact Laser Vibrometer in UAV Motor Shaft Runout Testing

Non-Contact Modal Measurement System

Revolutionary Vibration Monitoring for Next-Gen Range-Extender Engines: The OmniSensing MotionGo Laser Doppler Vibrometer Solution

Motor Shaft Runout and Yaw: Causes, Impacts, and Non-Contact Detection Solutions