Omnisensing Photonics' Non-Invasive and Online Monitoring Solution for Industrial Ultrasonic Welding

Welding is a common manufacturing process to join metals or other materials. With the advancement of modern industrial technology, ultrasonic welding has become a popular technique versus traditional ways due to its high efficiency, ease of operation, high versatility, and suitability for assembly lines, thus now widely used for both metal and plastic welding.

The effectiveness of ultrasonic welding relies on three interrelated parameters: amplitude, pressure, and time. These must be finely tuned to avoid under-welding or deformation. As battery packs grow in complexity (often 100+ layers), managing welding power output becomes increasingly critical.

Conventional PID control of ultrasonic drives cannot directly monitor the energy absorbed by the welded material. This gap in monitoring can lead to faulty connections, causing system-wide failures in serial or parallel battery configurations.Real-time, non-destructive, and independent quality monitoring is then needed, but current methods fall short.

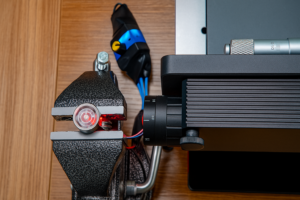

Omnisensing Photonics has developed an innovative online, non-contact monitoring solution using its advanced smart laser Doppler vibrometry technology. At the core of this solution is a miniaturized laser vibration sensor built on a revolutionary photonic integrated chip. This compact chip integrates a laser interferometer, signal processor, battery, and communication module—all within a device no larger than a matchbox. The result is a low-power, highly compact, and cost-effective solution that significantly enhances testing efficiency and scalability.

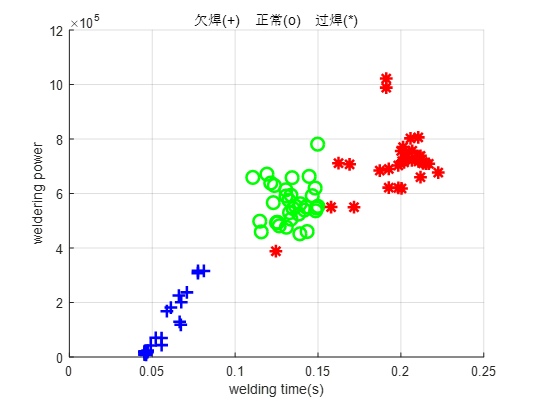

With 105 labeled field samples, machine learning models effectively distinguished between faulty and acceptable welds, as shown in Figure. The results confirm the sensor’s ability to identify structural defects like micro-holes or inconsistencies due to subjective human judgment.

For more details, please download the white paper.

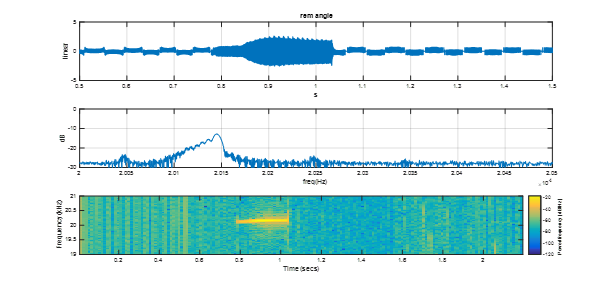

Figure 1:raw data welding example

Figure 2:ML models to qualitatively categorize welding quality

Application of Compact Laser Vibrometer in UAV Motor Shaft Runout Testing

Revolutionary Vibration Monitoring for Next-Gen Range-Extender Engines: The OmniSensing MotionGo Laser Doppler Vibrometer Solution

Motor Shaft Runout and Yaw: Causes, Impacts, and Non-Contact Detection Solutions

Omnisensing Photonics’ Non-Invasive and Online Monitoring Solution for Industrial Ultrasonic Welding