Application of Omnisensing Laser Vibrometer in UAV Motor Shaft Runout Testing

Introduction

With the rapid advancement of unmanned aerial vehicles (UAVs), ensuring motor reliability and precision performance has become a critical engineering challenge. One of the key indicators of UAV motor health is shaft runout—a factor that directly impacts vibration, noise, and overall operational efficiency. Traditional measurement methods often require direct contact and can introduce errors. In contrast, laser vibrometers provide a non-contact, high-precision solution for detecting shaft runout.

This white paper highlights the application of Omnisensing’s laser vibrometer technology in UAV motor shaft runout testing, demonstrating how it enhances measurement accuracy, efficiency, and reliability.

What is a Laser Vibrometer?

A laser vibrometer is an optical measurement instrument that leverages the Doppler effect to detect vibrations and displacements on a target surface. Unlike accelerometers or strain gauges, a laser vibrometer does not physically touch the test object, ensuring:

High accuracy

Wide frequency response

Minimal measurement interference

Omnisensing laser vibrometers are designed for compact and precision engineering applications, making them ideal for UAV motor shaft testing.

The Challenge: UAV Motor Shaft Runout

UAV motors operate at high rotational speeds and are exposed to complex aerodynamic forces. Even minor shaft runout can cause:

Increased vibration and acoustic noise

Reduced energy efficiency

Premature wear and failure of bearings

Degraded flight stability and control accuracy

Detecting shaft runout early is essential for UAV manufacturers to maintain quality assurance and long-term reliability.

Omnisensing Laser Vibrometer Solution

The Omnisensing laser vibrometer provides a superior approach to shaft runout detection in UAV motors. Its unique advantages include:

Key Benefits

Non-contact measurement – Eliminates mass-loading effects caused by traditional sensors.

High precision – Sub-nanometer resolution enables detection of micro-scale runout.

Real-time analysis – Captures dynamic vibration patterns during high-speed motor operation.

Wide bandwidth – Suitable for both low-frequency and high-frequency vibration modes.

Easy integration – Compact form factor allows convenient setup in UAV production lines.

Application Workflow

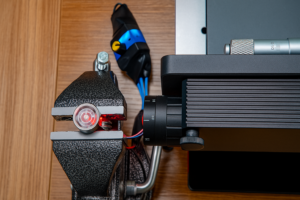

Setup: The UAV motor is fixed on a test bench.

Laser Alignment: The laser vibrometer is aimed at the rotating shaft surface.

Data Collection: Vibration displacement and acceleration signals are captured.

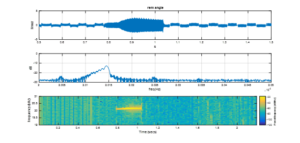

Runout Analysis: Software processes vibration data to identify shaft misalignment. Time domain and Frequency domain analysis.

Quality Control: Manufacturers receive precise feedback for motor calibration.

Case Study: UAV Motor Shaft Testing

In a recent Omnisensing application case, the laser vibrometer was used to evaluate shaft runout on UAV brushless motors. Key results included:

Detection of shaft deviations as small as 8 µm

- The frequency is 165Hz for low rpm

Identification of early bearing wear indicators

Reduction in testing time by 30% compared to contact methods

Improved motor reliability and lifespan in UAV field tests

Conclusion

The integration of Omnisensing laser vibrometers in UAV motor shaft runout testing represents a significant advancement in aerospace engineering quality control. By providing non-contact, high-precision, and real-time measurement capabilities, this solution ensures UAV motors achieve optimal performance, safety, and reliability.

For manufacturers seeking cutting-edge vibration measurement solutions, Omnisensing’s laser vibrometer technology offers a proven path toward innovation and competitive advantage.

About Omnisensing

Omnisensing Photonics is a leader in advanced optical measurement technologies, specializing in laser vibrometers for industrial, aerospace, and research applications. With a commitment to precision and innovation, Omnisensing helps global customers achieve superior measurement accuracy and operational efficiency.

Application of Compact Laser Vibrometer in UAV Motor Shaft Runout Testing

Revolutionary Vibration Monitoring for Next-Gen Range-Extender Engines: The OmniSensing MotionGo Laser Doppler Vibrometer Solution

Motor Shaft Runout and Yaw: Causes, Impacts, and Non-Contact Detection Solutions

Omnisensing Photonics’ Non-Invasive and Online Monitoring Solution for Industrial Ultrasonic Welding