Non-Contact Impact Measurement: Demonstrating the High-Speed Capabilities of the OmniSensing MotionFlex Laser Vibrometer

The Critical Need for Precision in High-Velocity Impact Testing

In industries ranging from automotive safety and consumer electronics to military defense and quality control, accurately measuring the mechanical response of components under high-speed impact is paramount. Traditional contact sensors, such as accelerometers, often suffer from mass loading effects, limited bandwidth, and complex wiring, which can compromise the integrity of the measurement, especially for small or light components.

To overcome these limitations, engineers are increasingly turning to non-contact methods. The laser vibrometer is the gold standard for high-bandwidth, non-invasive vibration and motion analysis. This white paper presents the experimental verification of the OmniSensing MotionFlex Laser Doppler Vibrometer (LDV) and its proven capability to meet and exceed demanding requirements for high-displacement and high-velocity impact measurement.

Introducing the OmniSensing MotionFlex Laser Vibrometer

The OmniSensing MotionFlex is engineered for exceptional performance in dynamic testing environments. It provides simultaneous, high-resolution data on displacement, velocity, and acceleration, making it an ideal tool for analyzing transient events like impact, shock, and component drop tests.

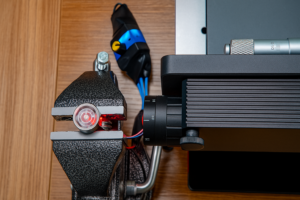

In a recent laboratory component impact experiment, the MotionFlex LDV was deployed to measure the response of two common engineering materials: a metal part and a plastic box. The tested objects were subjected to a swift strike from a metal rod to simulate a high-energy impact event.

Key Experimental Parameters

The robust capability of the OmniSensing LDV was demonstrated through aggressive data acquisition settings:

-

Sampling Frequency: 2 MHz

-

Test Frequency Range (Bandwidth): 0-25.6kHz

These parameters ensure the LDV captured the extremely fast, high-frequency oscillations characteristic of an impact event with exceptional detail.

Experimental Results: Proving High-Displacement Performance

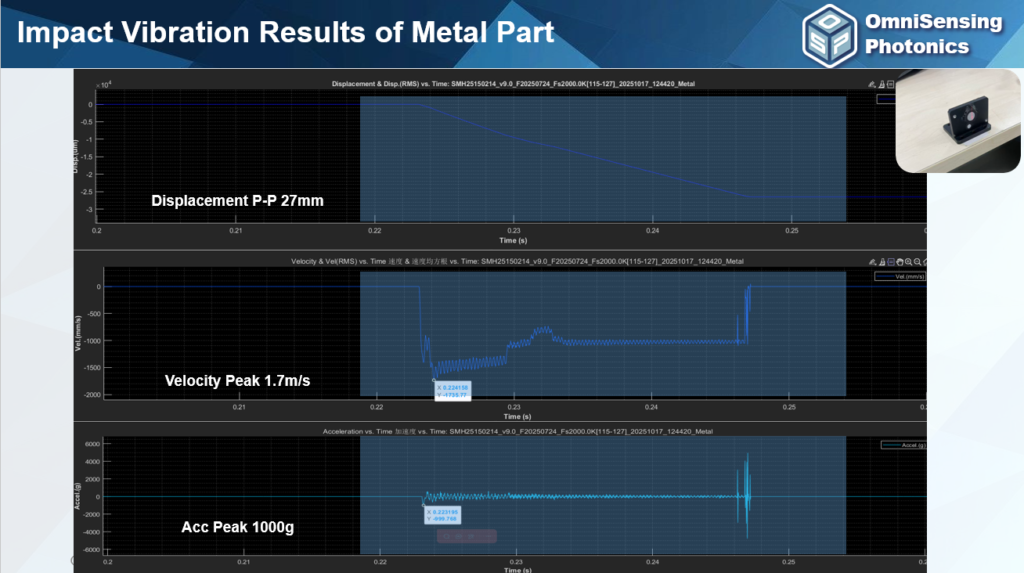

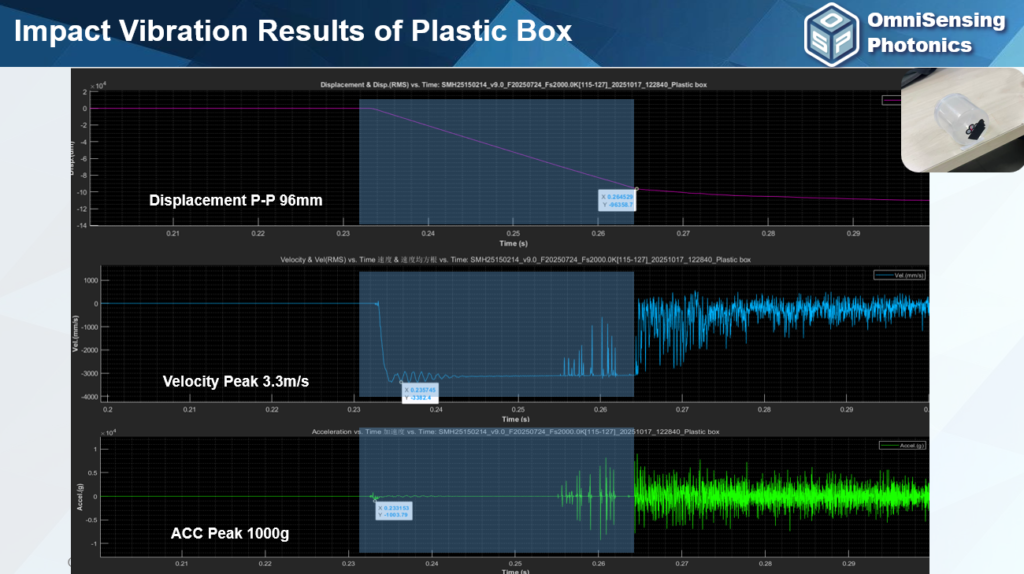

The core challenge in impact testing is often the combination of high speed and large displacement, which can push standard measurement equipment past its limits. The MotionFlex LDV successfully measured the full dynamics of the impact, as summarized below:

|

Tested Object |

Peak-to-Peak Displacement (P-P) |

Peak Velocity |

Peak Acceleration |

|---|---|---|---|

|

Metal Part |

27 mm |

1.7 m/s |

1000 g |

|

Plastic Box |

96 mm |

3.3 m/s |

1000 g |

Exceeding Industry Displacement Requirements

The test results confirmed the OmniSensing MotionFlex not only met but significantly surpassed key industry benchmarks. Specifically, the maximum measured Peak-to-Peak (P-P) displacement reached an impressive 96 mm on the plastic box. This far exceeds the typical 30 mm displacement requirement proposed by leading watch manufacturers , confirming the instrument’s suitability for testing components with significant temporary deformation.

Furthermore, the laboratory analysis demonstrated that the maximum velocity measurable by the MotionFlex laser vibrometer can comfortably exceed 15 m/s, validating its use in extremely high-speed applications.

Mitigating Real-World Measurement Artifacts

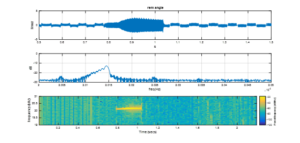

In any optical measurement, surface conditions can introduce noise. The test on the plastic box, which has a softer, more reflective surface than the metal part, showed a more pronounced speckle effect—a phenomenon manifesting as sudden jumps in velocity and acceleration at the tail end of the measurement signal.

A professional laser vibrometer solution must account for these real-world challenges. The data collected by the OmniSensing MotionFlex is high enough quality that post-processing methods, such as median filtering, can be reliably applied to eliminate this noise interference, ensuring the extracted motion data is accurate and clean.

Conclusion: The Non-Contact Advantage

The Component Impact Experiment successfully verified that the OmniSensing MotionFlex Laser Vibrometer is a powerful and reliable tool for the non-contact measurement of impact and shock phenomena.

By providing high-bandwidth, high-resolution data on displacement, velocity, and acceleration, the MotionFlex allows engineers to:

Analyze the full dynamic response of components without mass loading.

Meet and exceed rigorous industry standards for high-displacement and high-velocity motion.

Effectively mitigate optical noise through advanced signal processing capabilities.

For engineers seeking robust, high-precision impact testing solutions that eliminate the drawbacks of traditional contact sensors, the OmniSensing MotionFlex laser vibrometer offers the clear non-contact advantage.

To learn more about how the OmniSensing MotionFlex can revolutionize your component testing, contact our sales team today.

Application of Compact Laser Vibrometer in UAV Motor Shaft Runout Testing

Revolutionary Vibration Monitoring for Next-Gen Range-Extender Engines: The OmniSensing MotionGo Laser Doppler Vibrometer Solution

Motor Shaft Runout and Yaw: Causes, Impacts, and Non-Contact Detection Solutions

Omnisensing Photonics’ Non-Invasive and Online Monitoring Solution for Industrial Ultrasonic Welding