MotionFlex by Omnisensing Photonics Enables Laser Ultrasonic Measurement

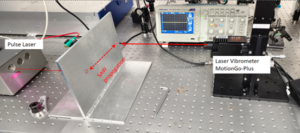

This article focuses on the laser ultrasonic measurement technology, introducing its principle, advantages, application fields, and challenges. It particularly emphasizes the enabling role of MotionGo Plus, a high – frequency laser Doppler vibrometer developed by Omnisensing Photonics, in this technology. The specific content is as follows:

Overview of Laser Ultrasonic Detection Technology

Principle

A high – energy pulsed laser beam is used to irradiate the surface of a material. The laser energy is converted into heat energy, causing local expansion of the material and generating ultrasonic waves. These ultrasonic waves propagate in the form of shear waves and longitudinal waves within the material, and their propagation characteristics are affected by the internal structure of the material. Another laser or sensor is used to detect the ultrasonic signals, and by analyzing these signals, the internal properties of the material can be evaluated.

Advantages

Non – contact measurement: It can perform non – destructive testing on sensitive or hard – to – access objects, making it suitable for applications such as aerospace and the detection of antique artworks.

High precision and sensitivity: It can conduct precise defect detection and structural analysis in extremely small areas, which is useful in fields like semiconductor manufacturing.

Strong adaptability: It can operate in extreme environments, making it applicable to industries such as energy production.

Fast and real – time: It enables real – time monitoring, improving production efficiency.

Application Fields

It is widely used in modern industry and the medical field. For example, in tumor diagnosis, especially breast cancer screening, it can clearly show the tumor boundary.

Challenges

Small signal amplitude: The signal amplitude is small and easily masked by background noise, requiring highly sensitive detection equipment.

Fast attenuation of high – frequency signals: High – frequency signals attenuate rapidly, affecting the detection depth and effect, and demanding high – frequency measurement sensitivity from the detector.

Difficulties in detector array and miniaturization: It is challenging to achieve detector array and miniaturization. High – precision array detection systems are complex and costly.

MotionGo Plus Enables Laser Ultrasonic Measurement

Excellent Performance

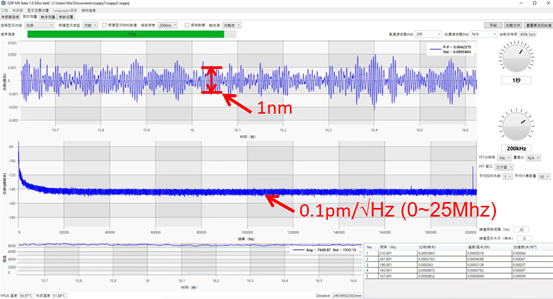

The noise performance in the high – frequency band has been optimized. It uses a low – noise, high – performance, and high – power laser. The noise floor is below 0.1 pm/√Hz, allowing it to detect weak high – frequency vibration signals less than 1 nanometer. It can measure sub – nanometer vibration signals in the time domain and accurately test vibration signals from DC to 25 MHz in the frequency domain, as shown in Figure 1.

High – Precision Synchronization

It can receive internal or external clock signals, with a synchronization accuracy better than 20 nanoseconds. This ensures the accuracy of signal capture time and improves the reliability and effectiveness of the signals.

Multiple Averaging Technology

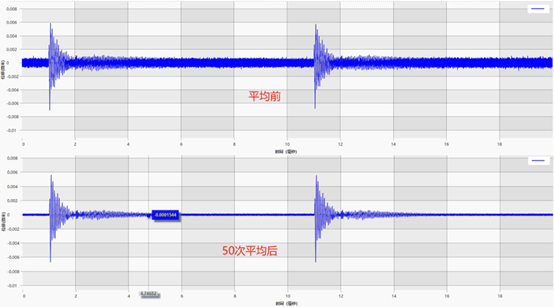

The software supports multiple averaging technology, which reduces the impact of random noise, improves the weak – signal detection ability, and enhances the system’s anti – interference ability. It enables clear observation of weak – signal characteristics, as shown in Figure 2.

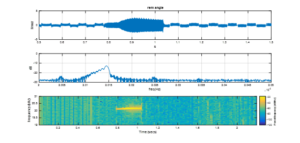

Chip-based Advantages

Based on Phox Photonics’ patented integrated optical chip, multiple optical paths are integrated on a single optoelectronic chip. This reduces the volume, power consumption, and batch – production cost of the vibrometer. It also makes it possible to generate detection images. In the future, it can improve the imaging speed and resolution, ensuring a low – cost, small – volume, and low – power -consumption system, which is suitable for high – precision imaging scenarios such as micro – structure analysis.

Figure 1: MotionGo - Plus' Large - Bandwidth and High - Sensitivity Detection Capability

Figure 2: Comparison of Signals Before and After Multiple Averaging Processing

Motor Shaft Runout and Yaw: Causes, Impacts, and Non-Contact Detection Solutions

Omnisensing Photonics’ Non-Invasive and Online Monitoring Solution for Industrial Ultrasonic Welding

Laser Doppler Vibrometer Solutions for Medical Ultrasonic Scalpel Testing

MotionFlex by Omnisensing Photonics Enables Laser Ultrasonic Measurement