Measuring the Propagation Characteristics of Ultrasonic Surface Waves Excited by Pulsed Lasers on the Back of Aluminum Plates

This document centers around the laser ultrasonic detection technology and specifically presents the application of Omnisensing Photonics’s MotionGo Plus in measuring the propagation characteristics of ultrasonic surface waves generated by pulsed lasers on the back of aluminum plates. The details are as follows:

Principles of Laser Ultrasonic Detection Technology

Laser Excitation: When a high-energy pulsed laser beam shines on the surface of a material, the energy is transformed into heat. This causes the material to expand instantaneously in a local area, thereby generating ultrasonic waves.

Ultrasonic Wave Propagation: Ultrasonic waves propagate within the material in the forms of shear waves and longitudinal waves. Their propagation characteristics are influenced by the internal structure of the material.

Ultrasonic Wave Detection: Another laser or a sensor is utilized to detect the ultrasonic wave signals. By analyzing these signals, we can assess the internal characteristics of the material. This technology is highly precise and sensitive, allowing for accurate defect detection and structure analysis in small areas. It holds great significance in fields like semiconductor manufacturing.

Experimental Process and Measurement

Ultrasonic Generation: High – frequency pulsed laser beams strike the front surface of the aluminum plate. The resulting thermal expansion triggers the generation of ultrasonic waves, including shear waves and longitudinal waves.

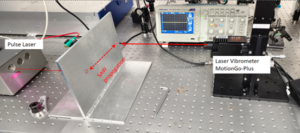

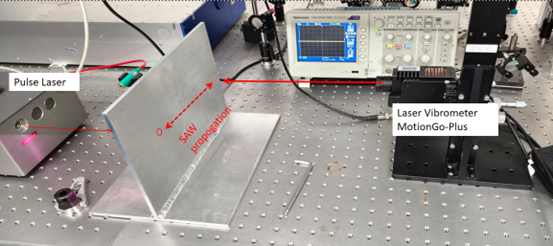

Measurement Equipment: The MotionGo Plus device is positioned on the back of the aluminum plate. Triggered by the clock signal of the laser, it conducts synchronous acquisition, precisely recording the arrival time of ultrasonic waves, as depicted in Figure 1.

Figure 1: MotionGo - Plus Measuring the Vibration Signals Excited by High - Frequency Pulses

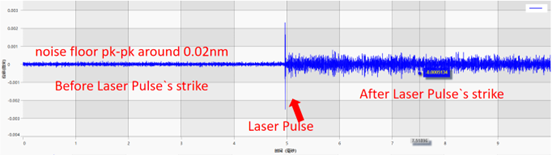

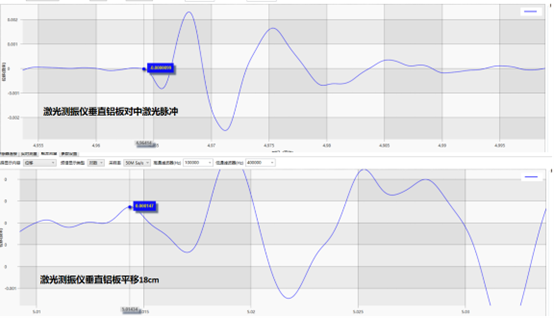

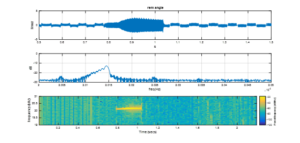

Data Analysis: Analyze the pulsed ultrasonic signals. For instance, the amplitude differences can be employed to determine the internal structure characteristics of the material and locate defects, as shown in Figure 2. By comparing the time signals measured at different points, we can obtain the wave velocity. In the experiment, the shear wave velocity is approximately 3500 m/s, and the longitudinal wave velocity is around 5800 m/s, as illustrated in Figure 3.

Figure 2: Pulsed Ultrasonic Signal Measured at One Location, with a Half - Peak Value of Approximately 1.2 nm and a Duration of Roughly 50 μs

Figure 3: Comparing Time Signals at Different Point Locations

Advantages of the MotionGo Plus Device

Designed for high – frequency testing, the MotionGo Plus device exhibits outstanding noise performance in the high – frequency band. It is equipped with a low – noise, high – performance, and high – power laser, and its noise floor is superior to that of MotionGo. In the time domain, it can measure vibration signals below the nanometer level, while in the frequency domain, it can accurately test vibration signals ranging from DC to 25 MHz. This makes it a viable solution for laser ultrasonic detection.

Motor Shaft Runout and Yaw: Causes, Impacts, and Non-Contact Detection Solutions

Omnisensing Photonics’ Non-Invasive and Online Monitoring Solution for Industrial Ultrasonic Welding

Laser Doppler Vibrometer Solutions for Medical Ultrasonic Scalpel Testing

MotionFlex by Omnisensing Photonics Enables Laser Ultrasonic Measurement